MENU

Skip menuResearch interests

My research interests focus on applying theory and numerical methods to problems in fluids with the goal of improving fundamental knowledge. I've worked on grid refinement, design optimization, computational fluid dynamics and some theoretical fluid dynamics. I have developed codes which numerically solve various partial differential equations using finite difference, finite element and finite volume methods. Below are some sample projects I've worked on.

Sample research projects:

- Curvature effects on ramp-induced shock wave/boundary layer interactions.

- Incipient separation in laminar ramp-induced shock wave/boundary-layer interactions.

- Force Measurements and Computational Validation of a Transonic Wing-Tip Flow

- Deformation method for grid refinement

- Data analysis tool for Fischer–Tropsch experiments I developed an approximately 2500 line Python module for reducing experiment data from Fischer–Tropsch reactions. Object-oriented design was used with common functionality factored out using inheritance. The data reduction task was complicated because data from multiple sources such as mass flow meters and gas chromatographs had to be correlated.

- CFD Simulations of Fischer-Tropsch reactor Worked under the supervision of Dr. Brian Dennis (co-advisor) to evaluate a patented reactor design using ANSYS Fluent. Simulations involved coupling heat transfer from fluid to solid. The deliverable was a final report on the efficacy of the proposed design.

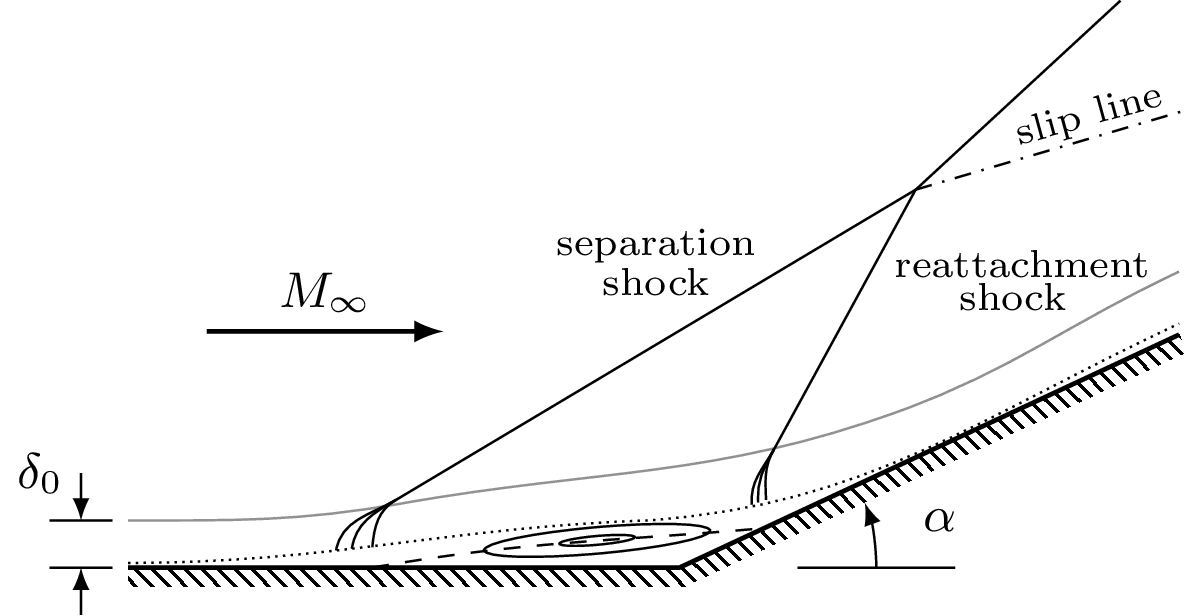

The purpose of this work is to investigate how different radii of curvature affect shock-induced separation. We make use of a compression ramp geometry with a circular arc to round out the corner. Approximately three hundred CFD flow solves were accomplished for different Mach numbers, Reynolds numbers and radii of curvature.

In this work, we made use of an asymptotic boundary layer theory, known as triple deck theory, as well as numerical solutions to the full set of governing equations to study incipient separation in supersonic flows. NASA's FUN3D code was used to solve the Navier-Stokes equations and a C++ code was developed to numerically solve the triple-deck equations. The triple-deck code is available in Codes. The work has been submitted to a scholarly journal. The results and conclusions will not be provided until a decision has been made by the reviewers.

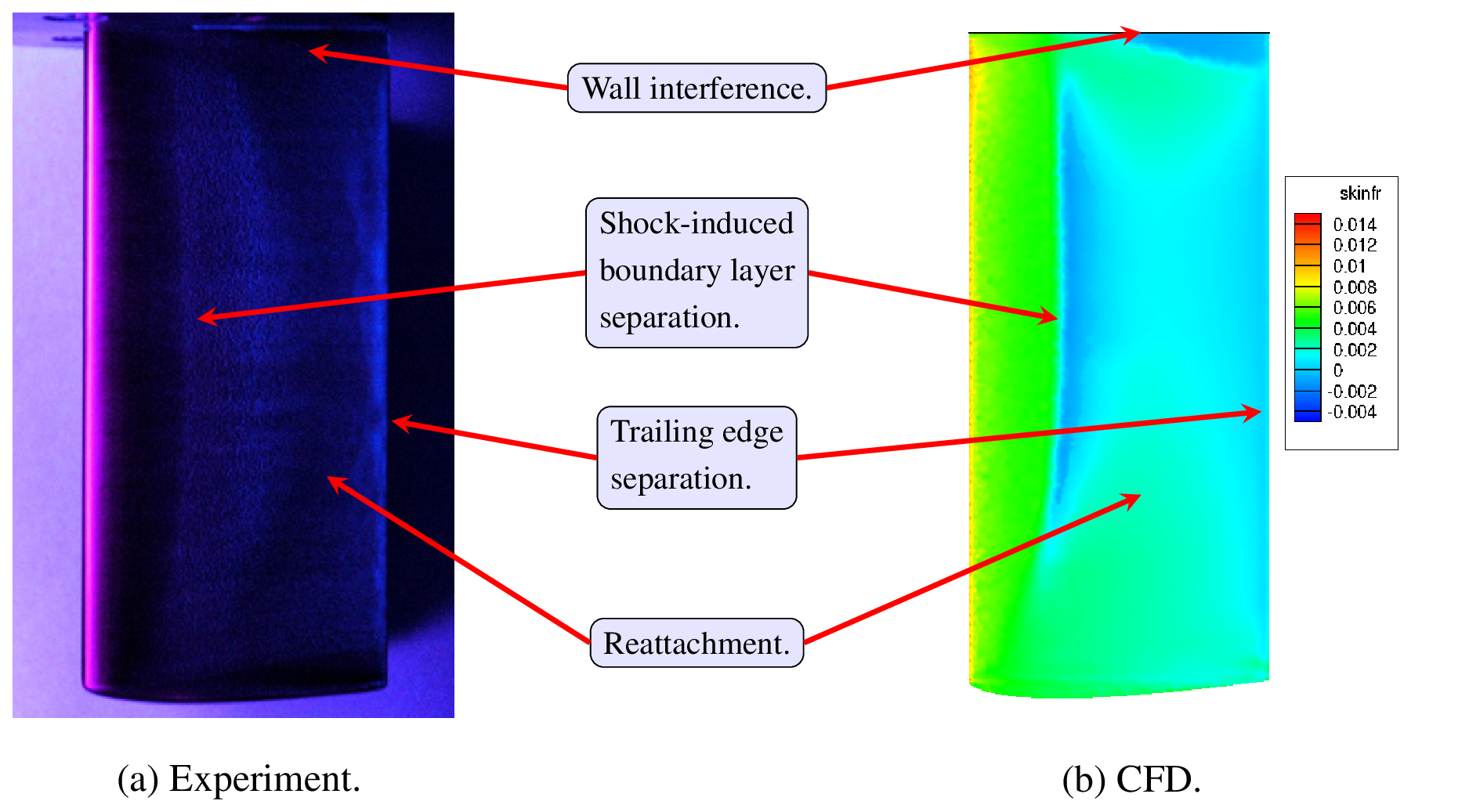

This effort was focused on applying a calibration technique from hypersonic shock tunnels to transonic Ludwieg tubes. The dynamic calibration was undertaken in order to remove the effects of propagating stress waves which arise due to the short run times of Ludwieg tubes. My role in this work was to provide CFD data for comparison with experimental data. NASA's FUN3D code was used to simulate the entire test section of the Ludwieg tube tunnel at UT Arlington. A mesh study along with FUN3D's built-in feature-based refinement were used to ensure grid independent results. Results were compared in terms of force coefficients and surface flow visualization. Experimental surface flow visualization was accomplished using fluorescent chalk which was ground up and suspended in mineral oil. This oil was then placed on the wing prior to the wind tunnel run. Comparison between CFD and experimental SFV revealed that some flow features had previously been misidentified.

Conference paper from 30th International Symposium on Shock Waves (ISSW)

Presentation from 30th ISSW

AIAA Journal of Aircraft paper

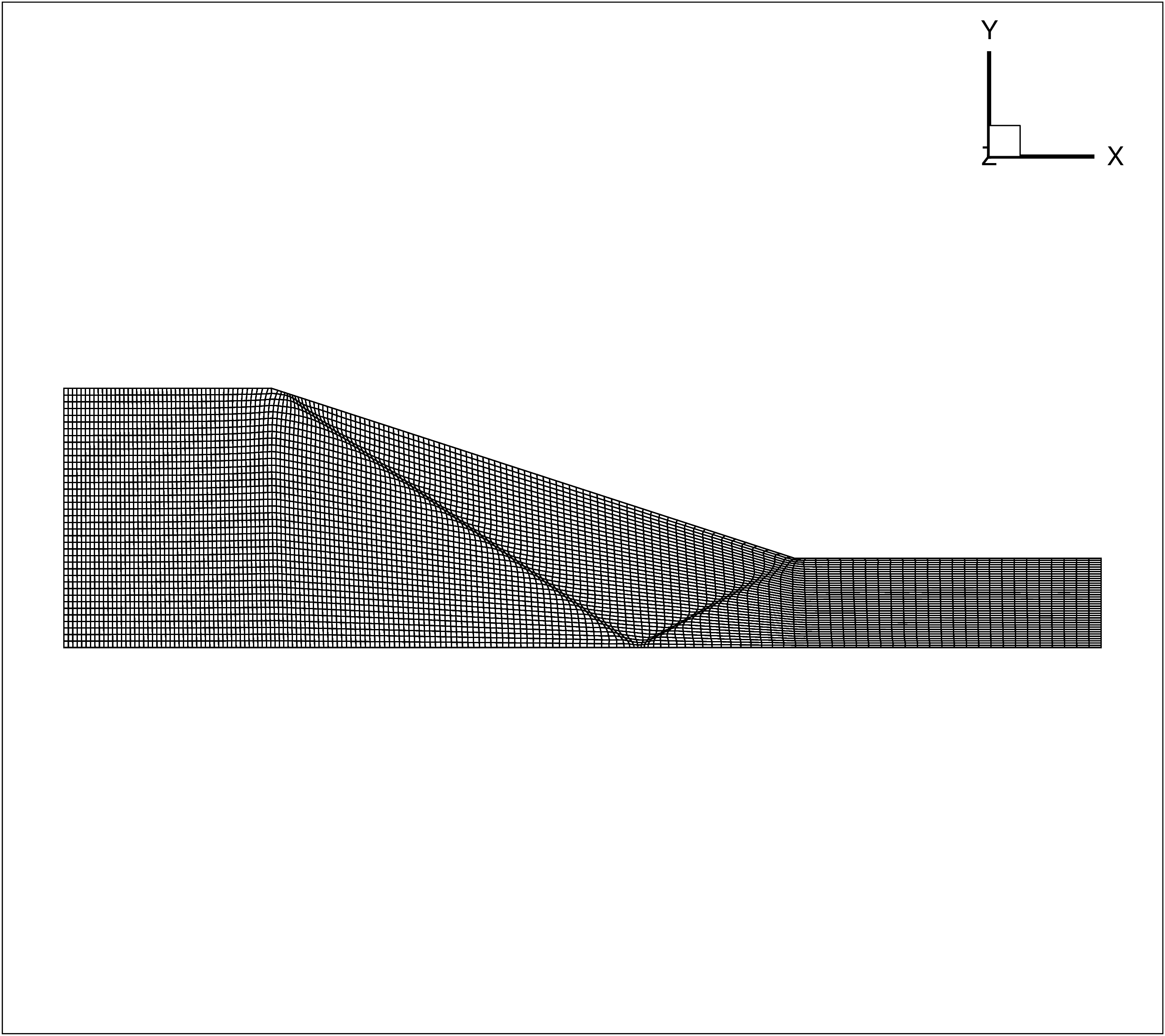

This work emerged from a course that I took on mesh refinement. I developed a C++ code which implemented the Liao's deformation method for grid adaptation. This code is also available in Codes. The deformation method requires solving Poisson's equation. I used second-order accurate finite differences and successive overrelaxation to solve the system. NASA's CFL3D code, which was coupled with my deformation method code, was compared against an h-refinement feature of ANSYS Fluent. Results and discussion can be seen in the below conference paper.

2015 AIAA SciTech paper